Navigating the Turbulence: Lithium-Ion EV Battery Market Correction and the Road Ahead

Until recently, U.S. carmakers planned $100 billion in robust EV production expansions. Ford, General Motors, and others have cut back on plans to accelerate EV manufacturing. Ford Motor Co. shifted gears in the fall of 2023, announcing a $12 billion pull-back in its EV manufacturing plans. The companies say they have problems with EV production. One problem is that electric vehicles are not generating enough consumer demand. This has created a profitability issue. In the first quarter of 2023, Ford said it lost $58,333 for every EV the company sold.

Michigan Was Hit Hard

Michigan has become a hotbed of EV battery production. As a result, the state has experienced some of the worst effects of the slowdown. Production of two electric trucks at Orion Assembly, Michigan, will have its opening delayed from 2024 to late 2025, GM spokesperson Jim Cain said. GM’s Ultium Cells battery factory in Delta Township, Michigan, remains on schedule. Ford laid off 700 workers while scaling back production of the F-150 Lightning pickup at the same time. In November, Michigan-based EV battery startup Our Next Energy (ONE), cut its workforce by 25% as part of a “revised business plan,” according to company representatives.

Companies Experience Layoffs, Delays and Slowdowns

South Korea’s LG Energy Solution cut 170 workers in Holland, comprising 10% of its staff. The company supplies batteries to GM and said the previously planned expansion’s full hiring timeline will be pushed back from 2025 to 2027. Next-gen EV battery company Freye Battery laid off 78 staff members from plants in Norway and Georgia. Enovix cut 185 workers in California. South Korean battery manufacturer SK On recently reduced its workforce in the U.S. The company’s move cut more than 100 workers at one of its two battery plants in Georgia in September.

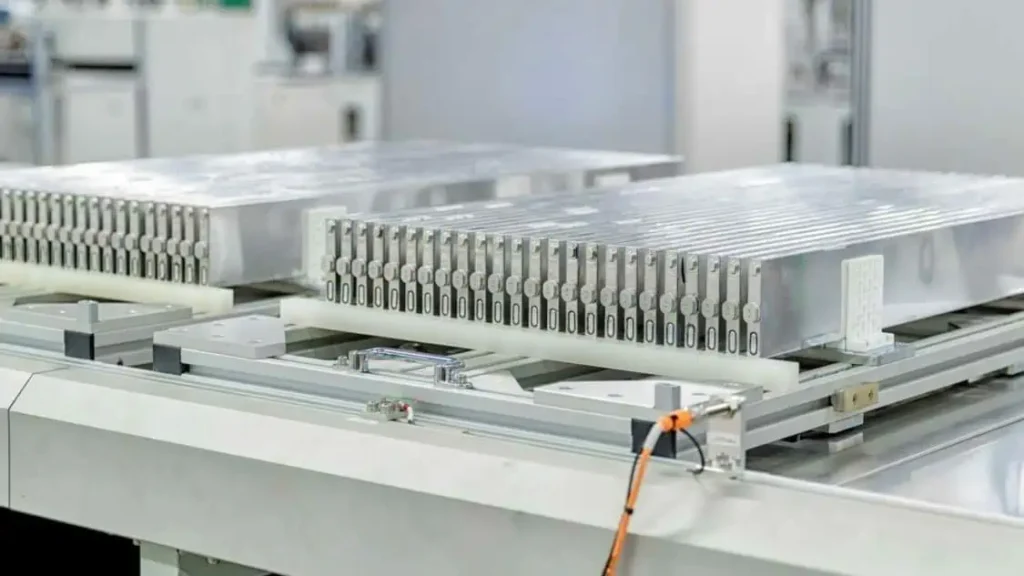

Many Companies in the U.S. Are Working On Manufacturing LFP Battery Cells

Lithium iron phosphate (LFP) batteries are one of the new EV battery technologies that are gaining traction. Major automotive producers like Ford are introducing LFP. With a low risk of overheating, LFP batteries are among the safest types of lithium-ion batteries. They do not contain heavy metals such as cobalt or nickel. Nickel sourcing has been in the spotlight due to sustainability concerns. Human rights and environmental abuses have been an issue in nickel supply chains.

ONE is currently delivering prototype versions of its LFP battery packs to several companies for testing. ONE is joining other companies in developing a domestic battery supply chain. These companies hope to benefit from President Biden’s Inflation Reduction Act as a result.

Domestic Battery Production Is a Requirement of the Current Federal EV Tax Credit

New rules within the Inflation Reduction Act block “Foreign Entities of Concern,” which include countries like China, North Korea, and Russia. Ford recently released news that their top-selling electric vehicles will be losing federal EV tax credits on January 1, 2024, because of this. Chinese company CATL provides LFP batteries for Ford’s Mustang Mach-E.

Lithium Prices Have Dropped

Lithium has experienced a significant price decline over the past year. The benchmark price for lithium, the most common component of current EV batteries, is down 80% year-over-year. Its record-high price was in November 2022 due to a rising demand. Goldman Sachs reported that lithium prices have dropped significantly, together with steep drops for nickel and cobalt. The company’s report said battery prices are forecasted to fall by 40% from 2022 to 2025.

A Historic Increase in U.S. BEV Sales Was Not Enough

For the first time ever, EVs passed the historic one million sold mark this year in the U.S. through the first 11 months of 2023. Battery electric vehicle (BEV) sales increased 50.7% year-over-year. The momentous news was released by the National Automobile Dealer Association (NADA). However, the sales increases were not enough or came too late to prevent cutbacks.

The EV Battery Industry Will Bounce Back, but When?

2022’s Inflation Reduction Act of 2022 introduced generous subsidies and requirements of local production for EV incentive eligibility. In spite of the slowdown, companies are expected to produce and sell more EV batteries than ever before in the future. But there may be more adjustments as the industry bounces back. Nearly 1,000 gigawatt-hours of an annual EV battery manufacturing capacity, in the form of new plants, is planned in North America by 2030.

The U.S. is strongly committed to producing more EV batteries. There are several reasons for this. One is to reduce dependence on foreign governments for EV batteries, such as China, the global EV battery industry leader. China produces 75% of the globe’s lithium-ion batteries, the most common battery type used in today’s EVs. The current political relationship between the U.S. and China is strained. One example of tension is the high tariffs still in place, which prevent low-priced Chinese EVs from gaining traction in the U.S. market.

Good News for EVs on the Horizon

Decreasing prices for battery metals could help make EVs more competitive with traditional gas-powered cars more quickly. As companies recover from the slowdown, major growth in the EV market is expected for 2024. Experts predict that the EV tax credit, transitioning to a point-of-sale discount in 2024, will produce massive increases in sales. While some buyers are willing to wait for tax time to recover the tax credits earned from EV sales so far, the majority of buyers prefer a point-of-sale discount.

Automotive industry and EV industry experts disagree, some say there is no EV slowdown, others recognize that there is a slowdown. Regardless of which opinions are correct, one thing is for certain. That certainty is that the global EV revolution has gained too much momentum to be stopped. Gas-powered, internal combustion engine (ICE) vehicles will all be replaced by EVs at some point in history. The only question is how quickly that will happen. These cutbacks by OEMs have caused layoffs and other problems with the EV and battery industries. However, these problems will no doubt be resolved, and the EV movement will pick up more steam again. The future of the EV remains very bright.

Electric Vehicle Marketing Consultant, Writer and Editor. Publisher EVinfo.net.

Services