Prevent EV Corrosion with Termin-8R

The electric vehicle (EV) market has recently moved into the fast lane, in both the automotive and transportation industries. Electrification of transportation is coming, and it’s coming fast! As an EV owner or operator, one of the most important things you must not overlook is regular maintenance of the batteries, charge ports and charging stations.

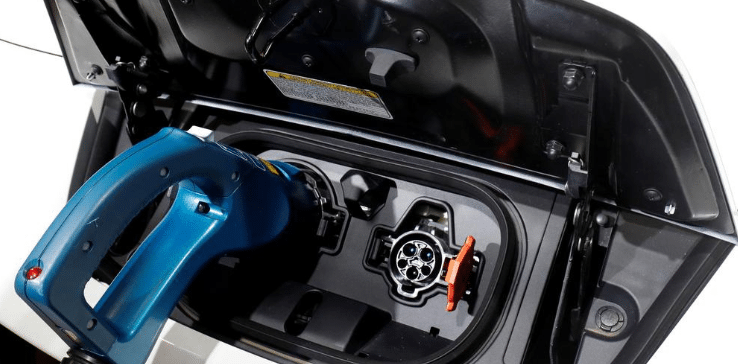

Not only are EV batteries much more expensive to replace than a regular car battery, they also take longer to repair – costing you valuable time and money. With an electric vehicle you need to maintain the battery to make sure it takes the charge, so the terminals must be clean. Equally important is making sure the charge port and charging station are clear of any corrosion, otherwise you will not be able to charge the battery properly.

If your EV is even a few years old, chances are your charge port is starting to show signs of corrosion. Allowing this corrosion to build up can lead to contact failure, overheating, shorting, and a reduction in charging efficiency. As a result, your battery will take longer to load – or fail to charge up fully.

What Is Corrosion, and How to Protect Your Equipment

Corrosion will occur in the presence of dissimilar metals, oxygen and electrolytes such as water, salt water and acids, in liquid or atmospheric forms. There are two practical ways to address corrosion: application of a Barrier Coating, or application of a Fluid Thin Film Coating (FTFC).

Termin-8R® Uses Fluid Thin Film Coating (FTFC) Technology to Stop Oxidation And Prevent Further Occurrence of The Corrosion Process

Termin-8R®’s FTFC technology allows it to creep into every nook and cavity, through seams, lap joints, rivets etc. providing superior surface penetration and displacing all moisture and other electrolytes which it encounters. Termin-8R®’s unique formulation contains oxygen scavengers and bio- degradable cleaning agents that AGGRESSIVELY lift dust, dirt, grime and surface contaminants to allow Termin- 8R® to attach “ionically” with metal forming a polar bond. The corrosion oxide is removed by Termin-8R®’s unique ingredients that separate oxides from the surface of metals.

Termin-8R®’s FTFC technology contains an outstanding Inhibitor Package that provides the needed rust and corrosion protection that continues to prevent further oxidation. The same properties that allow Termin-8R® to stop electrolysis make it ideal for treating electrical connections and equipment. With a dielectric of nearly 40,000 volts, Termin-8R® can safely be applied to control panels, circuit boards and switches, and electric motors for improved current flow. Termin-8R®’s high tech formulation is low in VOC’s resulting in long lasting protection with no adverse impact on sensitive components containing silicone, plastics or rubber.

Termin-8R® Protects Your Investment

By treating the electric charge port and the charging station with Termin-8R® you can be assured that your equipment will be safe from corrosion. Please make sure you also clean and treat the Universal Mobile Connector (UMC) by spraying Termin-8R® through the port and following up with a cotton swab. This will remove any corrosion and dirt from the UMC, then give it another shot of Termin-8R.

Protect Your Ride Now

info@spectraproducts.ca

888-381-2355