Argonne Announces Three Important EV Battery Breakthroughs

The Argonne National Laboratory has been working at light speed to bring better, more efficient and more cost-effective battery technologies to the electric vehicle (EV) industry and other industries. Recently, Argonne made three major battery announcements, summarized below.

Argonne Leads $50M Sodium-ion Innovation Push with DOE Funding

On November 21, 2024, The U.S. Department of Energy (DOE) announced allocating $50 million over five years to establish the Low-cost Earth-abundant Na-ion Storage (LENS) Consortium, led by Argonne National Laboratory and involving multiple national laboratories and universities. The initiative aims to develop advanced sodium-ion batteries as a safer, more sustainable alternative to lithium-ion batteries by using abundant and inexpensive materials like sodium, thereby reducing dependence on critical elements such as lithium, cobalt, and nickel.

Sodium-ion batteries offer cost-effective and supply chain-resilient options, though they currently face challenges like lower energy density compared to lithium-ion batteries. The consortium’s research will focus on high-energy electrode materials, improved electrolytes, and optimized battery cell designs. An industry advisory board will guide efforts to create a robust U.S. sodium-ion battery ecosystem.

With participation from 14 partners, including eight universities, LENS also aims to train the next generation of battery scientists. The project complements DOE’s broader sodium-ion research efforts, targeting applications in electric vehicles and grid storage.

Argonne National Laboratory Has Developed and Demonstrated an Innovative Set of Methods to Evaluate Long-Term Aging in Real-World Battery Cells

On October 31, Researchers at the DOE’s Argonne National Laboratory announced they have developed a groundbreaking nuclear magnetic resonance (NMR) spectroscopy technique to study long-term aging in commercial battery cells. This innovative, noninvasive method provides detailed insights into the chemical evolution of batteries over years of operation without damaging the cells. By leveraging the magnetic properties of atomic nuclei, the technique measures energy changes to analyze atomic and molecular structures, offering valuable data on battery materials.

The NMR capability is now available for battery researchers and manufacturers, enabling the study of nearly commercialized technologies, including batteries with silicon anodes. Silicon anodes, which have higher energy densities than traditional graphite anodes, are seen as key to improving the range of electric vehicles. This tool promises to become essential for advancing battery performance and longevity.

“The application of NMR to batteries has been limited to date. But with our powerful new capability, I hope that it will become ‘bread and butter’ for researchers and manufacturers who want to probe the long-term evolution of their batteries without opening them up.” — Baris Key, Argonne chemist

Silicon anodes in batteries face significant challenges due to their extreme volume changes—up to 400% expansion during charging and contraction during discharging—which can lead to cracking and instability. Additionally, the lithium silicides formed during charging are highly reactive, creating a less stable interface with the electrolyte.

Argonne researchers used advanced NMR spectroscopy, akin to medical MRIs, to track the behavior of lithium atoms in silicon-anode cells over a seven-month period. This technique provides detailed, noninvasive insights into the chemical processes affecting silicon-anode stability, aiding efforts to overcome these challenges and improve battery performance.

To better understand battery aging under real-world conditions, Argonne researchers used operando NMR, a technique that observes structural and electronic changes in real time while the battery operates. This approach contrasts with traditional methods that analyze cells only after disassembly, offering a more accurate view of how batteries age in practical applications like electric vehicles.

The team also simulated real-world conditions by fabricating battery cells using commercial-like manufacturing processes. This resulted in standardized cells with superior sealing and contacts compared to typical lab-made cells, enhancing the reliability and relevance of the findings.

“The cells are basically smaller versions of cells you would find in electric vehicles, computers and other devices,” said Evelyna Wang, an Argonne postdoctoral appointee and the study’s main author. “So they can perform well and hold up through full charge-discharge cycles over many months and even years. In contrast, many lab-made cells may only last for a week of cycling tests and cannot capture performance degradation over long periods. This study is the first ever to apply an operando characterization method to commercial-grade pouch battery cells.”

The Argonne team discovered that after charging, many lithium atoms were trapped in the silicon anode as lithium silicides, preventing them from being transported to the cathode during discharge. This trapped lithium reduced the available lithium for cycling, leading to a loss in energy-storage capacity. Additionally, the trapped lithium silicides reacted with the electrolyte, further degrading the cell’s performance. The team also found that adding magnesium salt to the electrolyte reduced the amount of trapped lithium silicides. These findings open the door to future research on chemical additives, electrolyte formulations, and silicon materials to minimize this issue.

A major advantage of NMR spectroscopy is its high sensitivity to light elements like lithium, silicon, carbon, and hydrogen, which are challenging to analyze with other methods. These new NMR techniques are versatile and not limited to silicon-anode batteries. They can also be applied to emerging technologies like sodium-ion and solid-state batteries, as well as to studying aging in other key battery components such as cathodes and electrolytes.

The research was supported by DOE’s Vehicle Technologies Office. A paper on the subject titled “Operando NMR characterization of cycled and calendar aged nanoparticulate silicon anodes for Li-ion batteries” was published recently in the Journal of Power Sources. Besides Argonne’s Key and Wang, authors include Marco Rodrigues, Sohyun Park and Fulya Dogan Key.

Argonne National Laboratory Has Developed a New Design That Dramatically Improves the Performance and Reduces the Costs of Lithium-Ion Batteries

On October 29, Argonne announced a breakthrough “dual-gradient” design for battery cathodes which substantially increases energy storage capacity, stability and lifetime while reducing costs. The breakthrough could accelerate widespread adoption of electric vehicles and grid batteries.

Argonne National Laboratory has developed a new lithium-ion battery design that enhances performance and reduces costs, advancing the adoption of electric vehicles (EVs) and grid energy storage while supporting global decarbonization. Building on decades of battery research, Argonne previously revolutionized lithium-ion technology in 2012 with a novel cathode material that optimized the composition of nickel, manganese, and cobalt to significantly increase energy density and durability.

“This breakthrough material represents an across-the-board improvement for batteries. It features higher storage capacity, robust stability and heat tolerance at high voltages, and longer lifetimes. Its high energy density enables production of smaller, lower-cost batteries, supporting widespread adoption of EVs and grid batteries,” said Khalil Amine, Argonne Distinguished Fellow and leader of Argonne’s Advanced Battery Technology team.

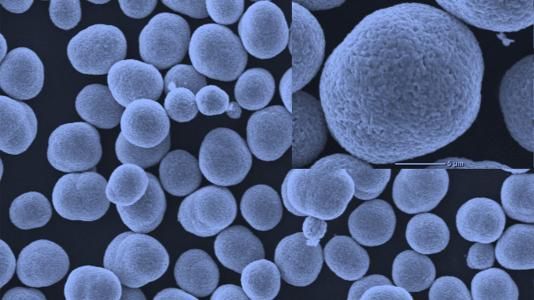

Argonne National Laboratory’s composition-gradient cathode design optimizes nickel, manganese, and cobalt distribution in lithium-ion batteries to balance energy density and stability. Nickel concentration decreases from the core to the surface, maximizing energy density while minimizing reactivity, enabling smaller, cost-effective batteries. The patented design features layered cathode particles that transport lithium ions efficiently during charging and discharging.

To improve performance for high-voltage operations, which can cause cathode degradation and safety concerns, Argonne introduced a new variation. This design transitions from a disordered cobalt-rich surface to an ordered, cobalt-free core. The disordered surface reduces cracking and reactivity, while the ordered core ensures efficient ion transport. This approach enhances capacity, stability, and safety at higher voltages, supporting the push for EVs with longer ranges and lower costs.

Argonne National Laboratory demonstrated the effectiveness of its new dual-gradient cathode design, which combines a cobalt-rich, disordered surface with a cobalt-free, ordered core. Extensive testing at DOE facilities confirmed the structure’s stability and durability during high-voltage operation. The dual-gradient particles retained 98% of their storage capacity after 500 charge-discharge cycles, indicating potential for significantly longer battery lifetimes.

The design also reduces cobalt usage, cutting interior cobalt concentration to under 2% compared to 10-20% in earlier designs. This addresses cost and environmental concerns associated with cobalt extraction. Additionally, the material exhibited improved heat tolerance, ensuring safer operation at high voltages. These advancements position the new cathode as a promising solution for longer-lasting, cost-effective, and sustainable lithium-ion batteries.

The Material is Ready to be Licensed

The Argonne study marks the first time that composition and structure gradients have been combined in a single cathode particle. It is expected to inspire new lines of research on cathodes that integrate different structures and compositions to enhance battery performance, and supported by DOE’s Vehicle Technologies Office.

“This breakthrough material represents an across-the-board improvement for batteries. Our patented design and fabrication process is ready to be licensed by industry.” said Amine.

In addition to Liu and Amine, authors of the Nature Energy paper include Lei Yu, Junxiang Liu, Alvin Dai, Tao Zhou, Jing Wang, Weiyuan Huang, Luxi Li, Matthew Li, Tianyi Li, Xiaojing Huang, Xianghui Xiao, Mingyuan Ge, Lu Ma, Zengqing Zhuo, Rachid Amine, Yong S. Chu, Wah-Keat Lee and Jianguo Wen.

Argonne National Laboratory is a federally funded research and development center in Lemont, Illinois. EVinfo.net urges you to contact your government representatives, and urge them to continue federal funding support for this groundbreaking and vitally important laboratory.

Electric Vehicle Marketing Consultant, Writer and Editor. Publisher EVinfo.net.

Services