EV Batteries May Last up to 40% Longer than Expected, Says New Study

A recent study from the SLAC-Stanford Battery Center suggests that electric vehicle (EV) batteries may last much longer in real-world driving conditions than previously predicted. Typically, battery scientists and engineers test battery life in laboratories using constant discharge and recharge cycles to predict longevity. However, these tests don’t necessarily reflect the varied driving conditions of everyday EV owners, such as heavy traffic, long highway trips, short city commutes, and extended periods of being parked. According to the new research, real-world usage could extend the lifespan of EV batteries by as much as a third beyond what researchers have forecasted.

This finding is significant for EV owners, as the battery remains one of the most expensive components of an electric vehicle, accounting for roughly a third of its total cost. Although battery prices have dropped by approximately 90% over the past 15 years, the cost of replacing an EV battery is still a concern for many consumers. The study’s results indicate that EV owners may not need to replace their expensive battery packs or purchase a new vehicle as quickly as anticipated, potentially saving money and reducing the long-term cost of ownership. This could be a positive development for both current and future EV commuters, offering the possibility of additional years of reliable use.

“We’ve not been testing EV batteries the right way,” said Simona Onori, senior author and an associate professor of energy science and engineering in the Stanford Doerr School of Sustainability. “To our surprise, real driving with frequent acceleration, braking that charges the batteries a bit, stopping to pop into a store, and letting the batteries rest for hours at a time, helps batteries last longer than we had thought based on industry standard lab tests.”

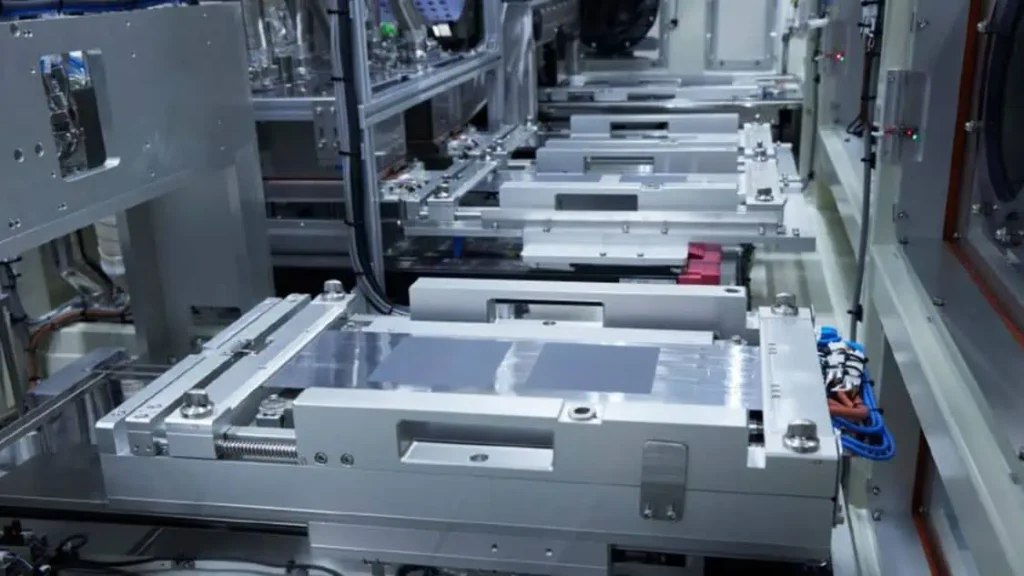

In their study, researchers at the SLAC-Stanford Battery Center designed four types of electric vehicle (EV) discharge profiles to better reflect real-world driving conditions. These ranged from the standard constant discharge model to dynamic discharging based on actual driving data. Over two years, the team tested 92 commercial lithium-ion batteries using these discharge profiles. The results showed that the more accurately the profiles mimicked real driving behavior, the longer the EV batteries lasted, with batteries exposed to dynamic driving patterns showing improved longevity.

Several factors contributed to this unexpected longevity, as identified by the study. A key tool was a machine learning algorithm that analyzed the extensive data the team collected. This algorithm helped to understand how dynamic discharge profiles impacted battery degradation, revealing that factors like driving style, traffic conditions, and varying recharge cycles have a significant influence on the lifespan of EV batteries. These findings suggest that real-world use could extend battery life beyond what traditional lab-based tests have predicted, offering consumers more value and reducing concerns about battery replacement.

The study revealed some surprising insights into how different driving behaviors affect the longevity of electric vehicle (EV) batteries. One of the key findings was that sharp, short accelerations actually correlated with slower battery degradation, contradicting long-standing assumptions among battery researchers, including the study’s team, that such acceleration peaks are detrimental to battery health. As explained by Alexis Geslin, one of the study’s lead authors, pressing the pedal hard during acceleration does not accelerate battery aging—in fact, it may slow it down. This finding challenges traditional thinking about how driving habits influence battery lifespan and offers new insights for EV owners and manufacturers alike.

Additionally, the research team explored how battery aging differs between frequent charge-discharge cycles and the natural aging that occurs simply from time. This distinction is important because, while batteries sitting unused in a drawer for years typically degrade and lose performance, the study suggests that the cycling nature of everyday use could have a different, less harmful effect on the battery’s health. The results imply that EV batteries could last longer in regular use, even under conditions that might have been previously considered damaging. This could reassure EV owners about the resilience and longevity of their batteries in real-world driving situations.

“We battery engineers have assumed that cycle aging is much more important than time-induced aging. That’s mostly true for commercial EVs like buses and delivery vans that are almost always either in use or being recharged,” said Geslin. “For consumers using their EVs to get to work, pick up their kids, go to the grocery store, but mostly not using them or even charging them, time becomes the predominant cause of aging over cycling.”

The study identified an optimal discharge rate, or “sweet spot,” that balances time-related aging and cycle-related aging, at least for the commercial batteries tested. This sweet spot lies within the range of typical consumer EV driving habits, meaning most drivers are already operating their vehicles in a way that promotes longer battery life. This discovery opens the door for automakers to update their EV battery management software, allowing them to optimize charging and discharging patterns to extend battery longevity based on real-world usage.

Beyond EV batteries, the study’s findings have broader implications for other energy storage applications and materials science. The principles uncovered could be applied to improve the lifespan of various materials and devices where aging is a critical factor. This includes plastics, glasses, solar cells, and even biomaterials used in medical implants. The research not only enhances our understanding of battery longevity but also offers valuable insights that could lead to longer-lasting, more efficient materials in a wide range of industries.