GM and LG Energy Solution to Commercialize Lithium Manganese-Rich Prismatic EV Batteries

In a major advancement for EV technology, General Motors and LG Energy Solution announced plans to commercialize lithium manganese-rich (LMR) prismatic battery cells for future GM electric trucks and full-size SUVs on May 13, 2025. This breakthrough builds on a longstanding collaboration between the two companies and represents a significant step forward in domestic battery innovation and sustainability.

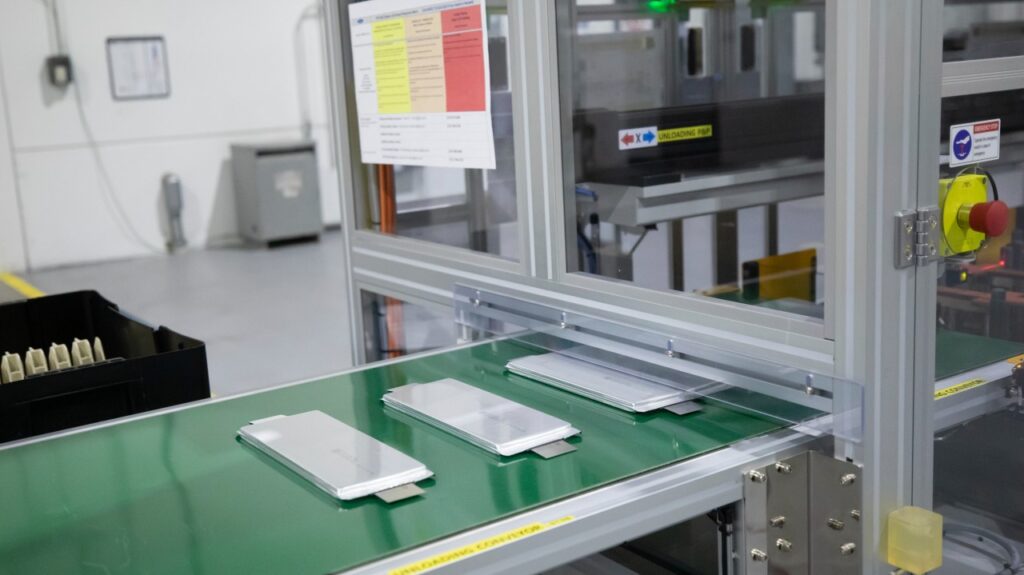

GM is poised to become the first automaker to deploy LMR batteries in electric vehicles. The Ultium Cells joint venture—formed by GM and LG Energy Solution—plans to start commercial production of LMR prismatic cells in the United States by 2028, with pre-production slated to begin at an LG Energy Solution facility by late 2027.

The final design of the LMR cells will be validated at GM’s Battery Cell Development Center in Warren, Michigan, which is expected to open earlier in 2027, and at LG Energy Solution’s research facilities.

Traditional battery cathodes rely on critical minerals such as cobalt, nickel, and manganese—with cobalt being the most costly. LMR chemistry shifts the balance by utilizing a higher proportion of manganese, a more abundant and affordable material, while still delivering exceptional performance.

Engineers at GM and LG Energy Solution have developed an LMR prismatic cell that achieves 33% higher energy density than today’s best lithium iron phosphate (LFP) cells—at a comparable cost. This means GM’s future electric trucks could offer more than 400 miles of range, while simultaneously lowering battery pack costs versus current high-nickel chemistry packs.

GM began researching manganese-rich lithium-ion batteries in 2015. At its Wallace Battery Cell Innovation Center, the company has spent years overcoming the technical hurdles of LMR, such as durability and performance. Through close collaboration with LG Energy Solution, GM engineers advanced everything from cathode materials to cell form factors and manufacturing processes.

LG Energy Solution brings deep expertise and a leading intellectual property portfolio to the table, holding more than 200 patents in LMR chemistry—dating back to its first patent in 2010.

This new LMR technology is designed to seamlessly integrate into GM’s Ultium battery platform and supply chain. It aligns with GM’s broader strategy to bolster domestic battery production and ensure more sustainable, North American sourcing of key materials like lithium, graphite, and manganese

From the revolutionary small-block V8 engine to OnStar and hands-free Super Cruise, GM has consistently pushed the envelope of what’s possible in automotive technology. With LMR battery innovation, the company is once again redefining the future—this time in the electric era

By combining advanced chemistry, cost-effective design, and strategic partnerships, GM and LG Energy Solution are paving the way for powerful, long-range EVs that are both accessible and American-made.

Ford Made Breakthrough With Lithium Manganese Rich (LMR) Battery Chemistry in April

In April, EVinfo.net reported that Charles Poon, Director, Electrified Propulsion Engineering at Ford Motor Company announced a breakthrough in Lithium Manganese Rich (LMR) battery chemistry — a game-changing advancement poised to reshape the EV landscape.

This is far from a theoretical breakthrough. Ford is actively scaling its LMR cell technology, with second-generation LMR cells already being produced on its pilot line. The company aims to integrate this cutting-edge chemistry into its next generation of vehicles before the decade is out.

Electric Vehicle Marketing Consultant, Writer and Editor. Publisher EVinfo.net.

Services