Gwangju Institute of Science and Technology Scientists Develop a Universal Method for Improving the Lifespan of Lithium-Ion Batteries

The advent of electric vehicles has given rise to the demand for lithium-ion batteries with high energy densities. This has led to the development of anodes with large charge storage capacity. Unfortunately, this storage capacity tends to degrade over multiple charge/discharge cycles, reducing the battery life. The challenge thus lies in engineering battery components that not only meet the energy requirements of modern electric vehicles, but also maintain their performance over an extended period, consequently prolonging battery lifespan.

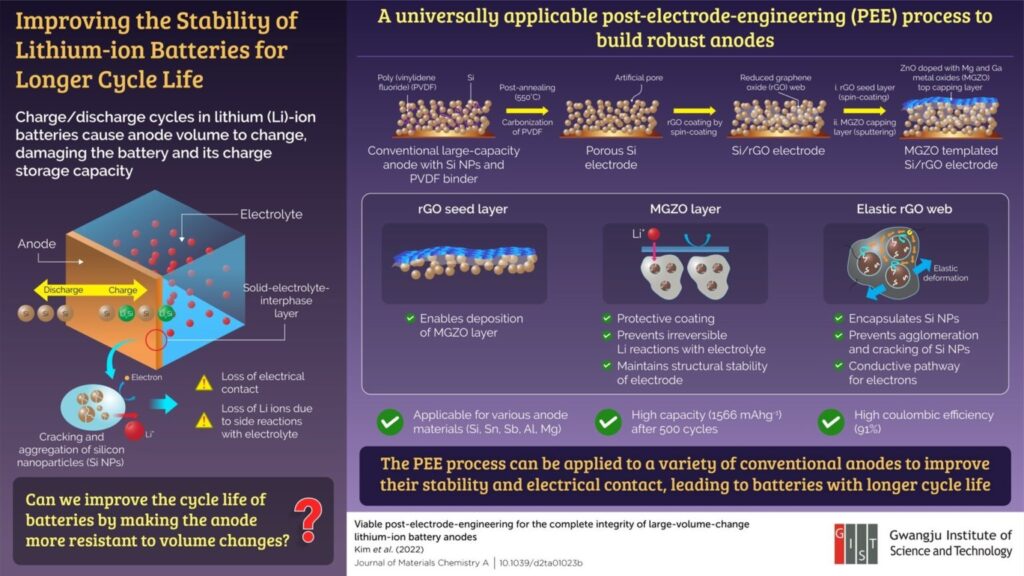

The relatively short lifespan of batteries can be attributed to an irreversible volume change in the anode during cycling, which results in the degradation of electrical contacts and structural collapse. In the charging process, lithium ions migrate from the cathode and combine with the nanoparticles present in the anode. Conversely, during the discharging phase, these lithium ions return to the cathode.

Over time, the nanoparticles within the anode crack and aggregate together at the electrode-electrolyte interface, leading to an electrical disconnection and consequently, reducing the charge that the anode can store or transport. However, a glimmer of hope arises from a recent study published online on 21 March 2022 in the Journal of Materials Chemistry A. Researchers at the Gwangju Institute of Science and Technology (GIST) in Korea have devised a novel method for modifying conventional anodes to enhance the cycling performance of the battery, paving the way for future improvements in battery technology.

“As one of the research groups engaged in this field, we wanted to develop an electrode process that would be able to increase the energy density in line with the rapid growth of the battery industry,” says Professor Hyeong-Jin Kim, one of the corresponding authors of the study.

The innovative strategy involves toughening the anode and rendering it more resistant to volume alterations by encasing the nanoparticles in a web-like formation. To illustrate their technique, researchers utilized a typical anode composed of silicon nanoparticles fortified by a polymer binder, polyvinylidene fluoride (PVDF). The team heated the anode using an annealing process to eliminate the binder, which left space for the insertion of a reduced graphene oxide (rGO) solution. The rGO dried to form a web that secured the silicon nanoparticles, mitigating the occurrence of cracks.

In addition, the web served as a conductive route for electrons, facilitating the interaction of nanoparticles with lithium. The researchers employed a method known as “spin coating” to apply the rGO coating to the anode surface. This rGO layer acted as a foundation for the subsequent deposition of a protective layer constituted of zinc oxide, magnesium, and gallium metal oxides (MGZO). The MGZO layer bestowed structural solidity to the anode. Impressively, upon examination, it was found that the modified anode was able to retain the majority of its charge even after numerous charge/discharge cycles.

“The structure retained a high storage capacity of 1566 mA h g-1 after 500 cycles and showed 91% coulombic efficiency, which relates to the battery life. This could pave the way for electric vehicles that enable us to drive long distances on one-time charging,” highlights Prof. Kim.

While the researchers at GIST primarily focused on silicon anodes in their study, their innovative method holds significant potential for other anode materials as well. Elements such as tin (Sn), antimony (Sb), aluminum (Al), and magnesium (Mg), commonly used in battery technology, could equally benefit from this approach. The universality of this method is one of its most promising aspects, as it can be applied to anodes regardless of their manufacturing process. Consequently, the implications for battery life enhancement are extensive and wide-reaching. This innovation, therefore, could usher in a new era in battery technology, making long-lasting, efficient power sources a tangible reality.

Title of original paper: Viable post-electrode-engineering for the complete integrity of large-volume-change lithium-ion battery anodes

Journal: Journal of Materials Chemistry A