Subaru, Toyota, and Mazda Commit to New Carbon-Neutral Engine Development

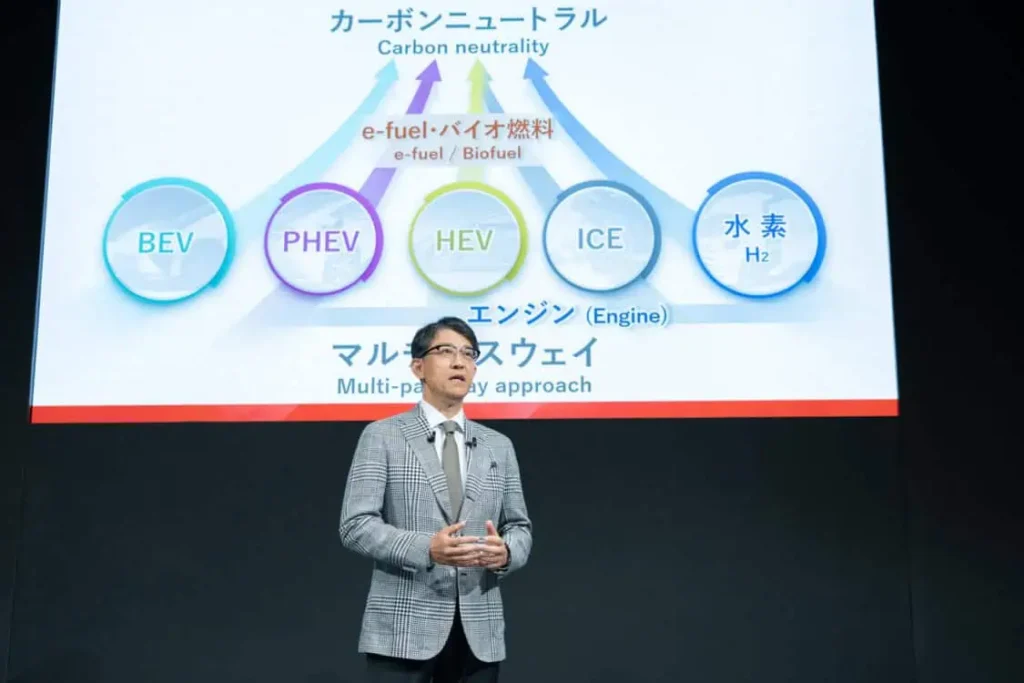

At the end of May, Toyota made the announcement that Subaru Corporation, Toyota Motor Corporation, and Mazda Motor Corporation are partnering up, dedicating significant resources to developing new carbon-neutral fuel engines that seamlessly blend internal combustion engines (ICEs) with electric drive units.

One of the key objectives of their partnership and development efforts is to optimize the synergy between motors, batteries, and other electric components. By creating more compact and efficient engines, they aim to transform vehicle packaging, enabling sleek designs and enhanced aerodynamic performance.

“In order to provide our customers with diverse options to achieve carbon neutrality, it is necessary to take on the challenge of evolving engines that are in tune with the energy environment of the future,” stated Koji Sato, President, Member of the Board of Directors and CEO, Toyota Motor Corporation. “The three companies, which share the same aspirations, will refine engine technologies through friendly competition.”

Masahiro Moro, Representative Director, President and CEO, Mazda Motor Corporation also highlighted, “We will continue to offer customers exciting cars by honing internal combustion engines for the electrification era and expanding the multi-pathway possibilities for achieving carbon neutrality. Given the rotary engine’s compatibility with electrification and carbon-neutral fuels, Mazda will continue to develop the technology through co-creation and competition to ensure it can contribute broadly to society.”

The next-generation, carbon-neutral (CN) engines are being designed to work harmoniously with e-fuels (synthetic fuels), biofuels, and liquid hydrogen, representing a significant move away from traditional fossil fuels. This compatibility will facilitate the wider adoption of clean energy alternatives, as well as meeting and exceeding increasingly stringent emissions regulations.

Electrofuels, Also Known as E-Fuels (Synthetic Fuels)

Electrofuels, also known as e-fuels, are engineered to be used in existing engines and infrastructure without significant modifications. The production of electrofuels involves the utilization of captured carbon dioxide or carbon monoxide, combined with hydrogen that is derived from water through electrolysis powered by low-carbon electricity sources.

The process is intrinsically designed to be carbon neutral, as the same amount of carbon dioxide used during manufacturing is released back into the atmosphere when the fuel is burned. This closed-loop system ensures a significantly reduced carbon footprint, making electrofuels an option for decreasing greenhouse gas emissions.

Electrofuels can be synthesized into various forms, with the primary targets being methanol and diesel. However, the technology also extends to other alcohols and carbon-containing gasses like methane and butane.

Biofuels

Unlike fossil fuels, which take millions of years to form, biofuels are produced over a relatively short period from biomass — organic materials such as plants, agricultural waste, and even domestic and industrial biowaste. This rapid production is one reason biofuels are considered a renewable energy source.

The primary use of biofuels is in transportation, where they serve as an alternative to gasoline and diesel. Biofuels are generally seen as carbon neutral, as the carbon they emit when burned is offset by the carbon absorbed by the biomass during its growth.

One major concern is the “food vs. fuel” debate, where the resources used for biofuel production could alternatively be used to grow food, potentially leading to food shortages. Additionally, sustainability assessments of biofuels often reveal a mixed picture, particularly when considering the land-use changes required and decimation of biodiversity to cultivate additional biofuel crops.

Liquid Hydrogen

Hydrogen vehicles harness the chemical energy of hydrogen to generate motive power, either through hydrogen fuel cells or internal combustion processes. While hydrogen fuel cells power electric motors by reacting hydrogen with oxygen, the internal combustion method is less common.

Despite its potential, hydrogen production is predominantly achieved through steam methane reforming, a process that emits significant amounts of carbon dioxide. Alternative production methods, like electrolysis of water or thermochemical processes using renewable resources, exist but remain costly.

The high carbon emissions linked to hydrogen production from natural gas, substantial capital costs, and the substantial energy inputs required for production are drawbacks. The low energy content per unit volume and the associated costs of building a refueling infrastructure add to the challenges. The Mirai, Toyota’s hydrogen car, has faced significant struggles recently in California.

Nissan Said No More ICE Funding

Referring to the collaboration between Toyota, Subaru, and Mazda on new carbon-neutral fuel engines, Francois Bailly, Nissan’s senior vice president and chief planning officer for the AMIEO (Africa, Middle East, India, Europe, and Oceania) region, told Drive, “Our future is EV.”

“e-Power is a stepping stone to get there, and each market will go at their own pace,” Bailly explained, adding, “We’re not investing in new powertrains for ICE, that’s for sure.”

Are CN Fuels Worth It?

We don’t agree with Subaru, Toyota, and Mazda’s pursuit of CN fuel engines. It’s very clear that BEVs (battery electric vehicles) are the most cost-effective and eco-friendly form of automotive transportation, and they will become the dominant form of global land-based transportation soon.

Spending time on other technologies that burn fuel of different types, even those described as carbon neutral, is not recommended. There are a variety of problems with the creation of these fuels, the distribution and storage of them, and building of the required infrastructure, which make them more carbon-intensive and less cost-effective than BEVs.

Electric Vehicle Marketing Consultant, Writer and Editor. Publisher EVinfo.net.

Portfolio: BillPierce.net