China and the Global Rise of Sodium-Ion Batteries: The U.S. Potential to Lead the Charge for EVs

In January 2024, BYD began constructing its first sodium-ion battery plant in Xuzhou, China. Investment into the project is 10 billion yuan (USD 1.4 billion), and the planned annual output capacity is 30 GWh. BYD’s subsidiary Findreams Battery signed an agreement with Huaihai Group to construct the plant. The two companies announced they would make batteries for micro electric vehicles (EVs) and e-scooters, as those micro-mobility EVs will make the best use of sodium-ion packs.

China is the global leader in EV production and adoption. The country has invested heavily in EVs, giving it a significant lead. China produces 75% of the world’s lithium-ion batteries used in EVs. This availability gives China an advantage in EV production. However, this may be changing with the advent of sodium-ion batteries.

Companies Using Sodium-Ion Batteries

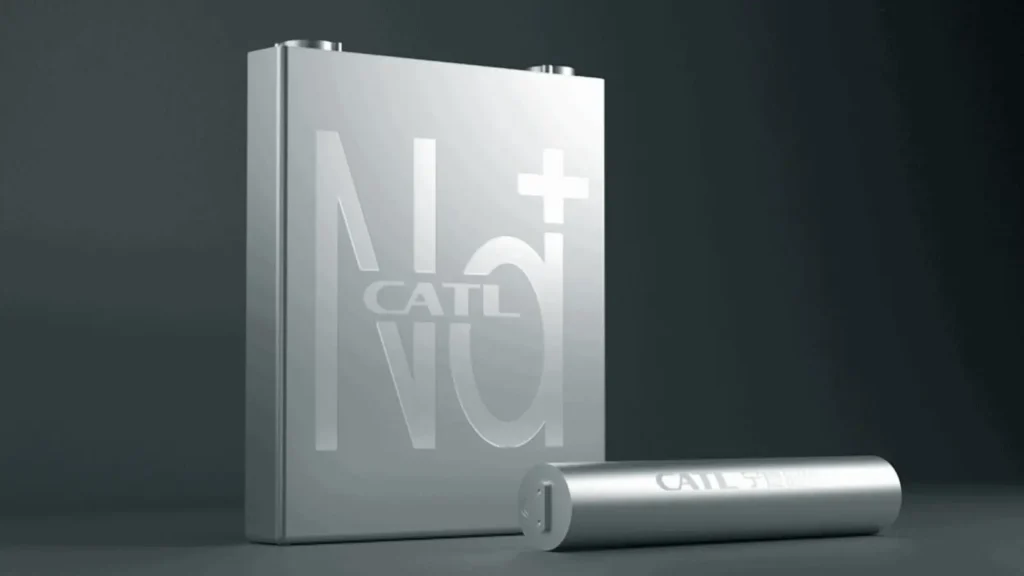

A Volkswagen-backed Chinese EV company, JAC Yiwei, produced a hatchback using a sodium-ion battery pack from HiNa Battery in December 2023. Jiangling Motors (JMC), a joint venture partner with Ford Motors, started mass production of another EV powered by a sodium-ion EV battery. The car is named the JMEV EV3, and Farasis Energy supplies the battery. CATL announced in April 2023 that the first automaker to use its sodium-ion batteries will be the Chery Auto iCar brand in China.

Benefits of Sodium-Ion Batteries for Electric Vehicles

Sodium-ion batteries (NIBs, Na+, SIBs, or Na-ion batteries) are rechargeable batteries that use sodium ions (Na+) as their charge carriers. In some cases, their cell construction and working principle are similar to lithium-ion batteries, but sodium replaces lithium as the cathode material.

Na-ion batteries are safer, offer a lower cost, have a longer life cycle, and are more environmentally sustainable than lithium-ion batteries. However, their lower energy density makes them more practical for smaller EVs, such as electric bikes, scooters, and low-speed vehicles (LSVs). Sodium carbonate (soda ash), the primary ingredient in sodium-ion batteries, is one of the most abundant resources on Earth. It is cheaper and more abundant than lithium, making it less susceptible to resource availability problems and price volatility. Growing usage of sodium-Ion EV batteries, produced in the U.S. and elsewhere, could reduce dependence on China during the green transportation transition.

Leading Manufacturers of Sodium-Ion Batteries Worldwide

Chinese companies lead the top five global sodium-ion EV battery manufacturers as of 2023. Those include CATL, and HiNa Battery Technology Co., Ltd. America’s top sodium-Ion EV battery manufacturer is Natron Energy, Inc., located in Santa Clara, California. The U.K. made the top five list with its Faradion, and France ranked with its Tiamat Sas.

America Leading Global Sodium Carbonate (Soda Ash) Production

According to Statista, total global production of soda ash was about 58 million metric tons (including both natural and synthetic soda ash). The United States was the leading producer of natural soda ash in 2022, producing 11 million metric tons. Turkey was second, with 4.4 million metric tons.

Global Production of Sodium-Ion Batteries for the EV Market

Coherent Market Insights estimated the global market for sodium-ion batteries to be worth USD $275.1 million in 2021. From 2022 to 2030, CMI predicted it to increase at a compound annual growth rate (CAGR) of 15.3%.

Could the U.S. Lead Global Sodium-Ion Battery Production?

It’s very possible the U.S. could lead global sodium-ion EV battery production. Because the U.S. is the largest producer of sodium carbonate, supply of raw materials is not a problem. According to the U.S. Environmental Defense Fund, manufacturers have announced more than $165 billion in investments in U.S. EV and EV battery manufacturing facilities in the last eight years. More than half of that (56 percent) has happened since the passage of the Inflation Reduction Act (IRA). The U.S. is currently very committed to clean energy production and investments. According to EDF, the investments and new facilities have created more than 179,000 new U.S. EV-related jobs, and experts expect the creation of more than 800,000 additional jobs in the broader economy.

As sodium-ion EV battery production efforts have begun only recently, significant investments have yet to happen for sodium batteries in the U.S. As demand for this new technology grows, investors will enable more building of new factories. However, America’s future of becoming a global producer of sodium-ion EV batteries may change depending on the outcomes of the 2024 elections.

Li-ion EV Batteries Still Important

When comparing a sodium-ion EV battery with a lithium-ion EV battery, it is not likely that sodium will replace lithium completely anytime soon. Because of its lower energy density, a sodium-ion EV battery isn’t feasible for larger EVs such as cars, SUVs, pickup trucks, and commercial electric vehicles. Because China currently produces 75% of the world’s lithium-ion batteries, it will continue to lead the Li-ion EV battery market for now. However, good news is on the horizon, as a significant discovery of lithium was reported in California, promising to make the U.S. the global lithium-ion EV battery leader.

A Staggering 18 Million-Ton Trove of Lithium, Valued at up to $540 Billion, Discovered at California’s Salton Sea

In December 2023, noteworthy news from the Department of Energy (DOE) came from an astounding discovery at the Salton Sea in California. The DOE awarded a $14.9 million grant to Berkshire Hathaway Energy to investigate the region around the Salton Sea, which is estimated to hold over 18 million tons of lithium. DOE estimates that Salton Sea lithium could furnish batteries for over 375 million electric vehicles, propelling the U.S. to the leading global lithium producer.

Lithium Iron Phosphate (LFP) Batteries

Lithium-ion batteries for EVs are nickel-based, using lithium nickel manganese cobalt oxide (NMC) and nickel cobalt aluminum oxide (NCA). Lithium iron phosphate (LFP) batteries use neither nickel nor cobalt; Both are supply-constrained and expensive. LFP batteries are gaining popularity in the U.S. Tesla and Ford are some American OEMs using LFP in new electric car models. LFP batteries already power most electric vehicles in the Chinese market.

The Future of Sodium-Ion Batteries

It’s becoming clear that sodium-ion EV batteries are quickly becoming more important. The U.S., as the world’s number one producer, has a significant supply of sodium carbonate. Will America become the leading global sodium-ion EV battery producer? With continued government support and a fast-increasing rate of EV adoption, that possibility looks very likely.

Electric Vehicle Marketing Consultant, Writer and Editor. Publisher EVinfo.net.

Portfolio: BillPierce.net